Revolutionize Production Management with Our Cloud-Based ERP Suite

Take Control of Your Inventory

-

Real-time updates with automated inventory tracking to keep accurate records of raw material levels

Real-time updates with automated inventory tracking to keep accurate records of raw material levels

-

Monitor delivery schedules and maintain optimal stock levels with supplier integration

Monitor delivery schedules and maintain optimal stock levels with supplier integration

-

Trace the usage of each batch of raw materials from delivery through to the finished product

Trace the usage of each batch of raw materials from delivery through to the finished product

Simplified Production Processes

-

Workflow automation to reduce manual errors and increase productivity

Workflow automation to reduce manual errors and increase productivity

-

Customizable templates to streamline your production processes

Customizable templates to streamline your production processes

-

Implement quality checks at critical stages to ensure the highest standards are met

Implement quality checks at critical stages to ensure the highest standards are met

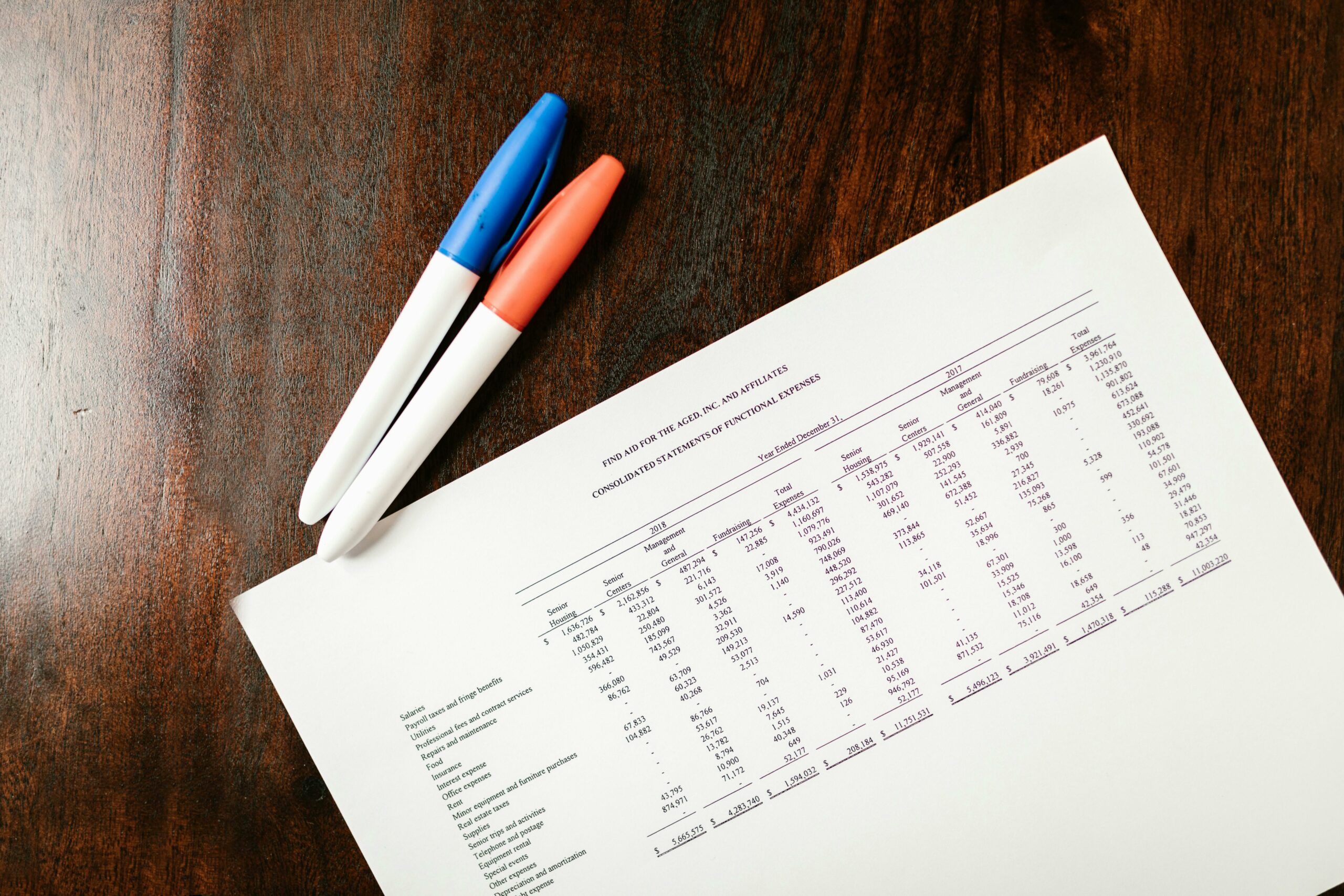

Comprehensive Usage Reports

-

Detailed reports to understand material usage patterns and identify areas for improvement

Detailed reports to understand material usage patterns and identify areas for improvement

-

Monitor waste levels and implement strategies to minimize scrap and rework

Monitor waste levels and implement strategies to minimize scrap and rework

-

Cost analysis to find opportunities for cost-saving measures

Cost analysis to find opportunities for cost-saving measures

Optimize Production & Reduce Costs. Get a Free Trial Today!

Frequently Asked Questions

Manufacturing ERP systems provide tools to streamline production planning and scheduling. You can manage bills of materials (BOMs), track raw material availability, and create production schedules that account for lead times and resource constraints. This helps optimize production flow, minimize delays, and ensure on-time delivery of finished goods.

Manufacturing ERP systems can help you identify areas for cost savings. They offer features for real-time material usage tracking, detailed cost analysis by product, and production line efficiency monitoring. This data allows you to optimize material usage, identify production bottlenecks, and make informed decisions that can significantly reduce overall costs.

Absolutely! Manufacturing ERP systems are designed to handle complex production environments. You can define multi-level BOMs for even the most intricate products, track work-in-progress (WIP) inventory efficiently, and ensure real-time visibility throughout the entire production process.

Posibolt ERP offers comprehensive reporting features, including inventory usage, cost analysis, and order history. These reports provide valuable insights to help you improve your manufacturing and make data-driven decisions.